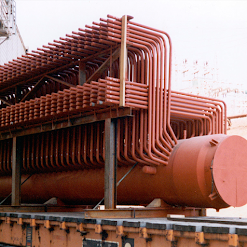

THERMAL POWER PLANT BOILER TUBES

Boiler Erection of Water Tubes......

How do I find a

leak in my boiler tube?

For detecting boiler

tube leaks, plant operating engineers constantly monitor boiler furnace

vacuum, which is maintained between a -10 to -20 mm water column, feed water

flow to the boiler drum from the feed pump, which must not

abruptly increase, the de-aerator level, the quantity of makeup water, and

hissing sounds

What causes boiler tube leaks?

While leaks can occur for any number of

reasons, the main causes of boiler tube leaks are tube corrosion,

unified unit corrosion, scale, thermal shock, and improper boiler water

treatment (post-installation).

While leaks can occur for any

number of reasons, the main causes of boiler tube leaks are tube corrosion,

unified unit corrosion, scale, thermal shock, and improper boiler water

treatment (post-installation). Preventing boiler tube leaks and failures starts

with understanding why they happen in the first place.

Tube Corrosion ?

Corrosion and the

breakdown of system components are the leading causes for boiler leaks. While

this can theoretically happen anywhere within the boiler, corrosion in the

tubes themselves is the most direct cause of leaks.

Tubes can become

corroded over time due to oxygen pitting. This is where there is excess oxygen

in the boiler water itself, which causes corrosion when iron or other materials

react with the oxygen molecules. The lower the temperature of the boiler

feedwater, the more oxygen is introduced to the boiler, causing a higher risk

for oxygen pitting within the tubes. By maintaining higher temperature

feedwater, you can reduce the risk of oxygen pitting.

To help prevent

tube corrosion and oxygen pitting, it’s best to use what’s known as an oxygen

scavenger, such as Charlady’s Boiler Deoxy products. Oxygen

scavengers are chemical agents, like sulphate or bisulphate ions, that react

and combine with dissolved oxygen to form sulphate, effectively removing excess

oxygen from your system.

HOW RESOLVE PROBLEM-------

Boiler Deoxy

Oxygen Scavengers

BOILER DEOXY Series products are used to prevent damaging corrosion

and/or pits from oxygen remaining in water in boiler systems. BOILER

DEOXY Series water treatment products are designed for this specific purpose.

They will not volatilize at any pressure nor will the reaction product formed

with oxygen volatilize. Industries that would most benefit by use: Water

Treatment, Utilities, and Commercial/Industrial.

What reduces oxidation within the tubing?

Nitrogen introduced

into the piping at

only about 2 psig pressure will prevent oxidation build-up on the inside of the pipe during brazing or soldering.

Tube Corrosion

Corrosion and the breakdown of system

components are the leading causes for boiler leaks. While this can

theoretically happen anywhere within the boiler, corrosion in the tubes

themselves is the most direct cause of leaks. Tubes can become corroded

over time due to oxygen pitting. This is where there is excess oxygen in the

boiler water itself, which causes corrosion when iron or other materials react

with the oxygen molecules. The lower the temperature of the boiler feedwater,

the more oxygen is introduced to the boiler, causing a higher risk for oxygen

pitting within the tubes. By maintaining higher temperature feedwater, you can

reduce the risk of oxygen pitting. To help prevent tube corrosion and

oxygen pitting, it’s best to use what’s known as an oxygen scavenger, such as

Charlady’s Boiler Deoxy products. Oxygen scavengers are chemical agents, like

Sulphate or bisulphate ions, that react and combine with dissolved oxygen to

form Sulphate, effectively removing excess oxygen from your system.

2. Unified Unit Corrosion

Beyond corrosion occurring in specific parts of

a boiler, units can also experience unified corrosion throughout the entire

system itself. This is typically caused by low pH levels throughout the boiler.

When you have pH levels below 8, your system is

in a state of increased corrosion due to the higher levels of acidity in the

water. Even though a pH of 7 is technically neutral, you run the risk of

dipping down into acidic levels if anything goes even slightly wrong.

At Charlady, we like to see boiler systems at

pH levels of 10 or above to ensure that corrosion throughout the unit is kept

to a minimum. To increase the pH level of your boiler water, it’s best to use a

pH or alkalinity adjuster, like our Boiler pH, which is a blend of chemicals

specifically designed to adjust the pH levels of your boiler.

3. Boiler Scale

Scale is another issue that can occur within

boilers which leads to tube leaks. Having scale build up in a boiler can impair

heat transfer, leading to tube leaks as pressure increases. This can also clog

blowdown valves and pressure release valves.

To reduce scale within a boiler, chemical

softeners and scale inhibitors can be used BOILER DE-SCALE products are

formulated specifically for boiler systems, boasting the ability to solubilize

contaminants commonly found in boiler feedwater in order to provide the

greatest potential for maintaining clean boiler heat transfer surfaces.

The BOILER DESCALE line and similar products

work well in conjuncture with scheduled boiler blowdowns. This is where water

is intentionally flushed or “blown out” from a boiler to help avoid the

build-up of scale and other impurities that can form during steam evaporation.

Blowdowns also can remove suspended solids that are present within the boiler,

which helps if there are any clogs or obstructions within your boiler tubes.

Scale is another issue that can occur within

boilers which leads to tube leaks. Having scale build up in a boiler can impair

heat transfer, leading to tube leaks as pressure increases. This can also clog

blowdown valves and pressure release valves.

To reduce scale within a boiler, chemical

softeners and scale inhibitors can be used BOILER DE-SCALE products are

formulated specifically for boiler systems, boasting the ability to solubilize

contaminants commonly found in boiler feedwater in order to provide the

greatest potential for maintaining clean boiler heat transfer surfaces.

The BOILER DESCALE line and similar products

work well in conjuncture with scheduled boiler blowdowns. This is where water

is intentionally flushed or “blown out” from a boiler to help avoid the

build-up of scale and other impurities that can form during steam evaporation.

Blowdowns also can remove suspended solids that are present within the boiler,

which helps if there are any clogs or obstructions within your boiler tubes.

4. Thermal Shock

Anyone who has ever tried to wash a warm dish

with cold water has experienced the quick and potentially devastating effects

of thermal shock. This can occur when cold water is introduced to a boiler. The

resulting thermal shock can cause a boiler’s tubes – as well as most any of its

components – to burst or leak.

The solution here is to make sure that your

boiler feedwater is at the proper temperature before being added to the boiler.

Anyone who has ever tried to wash a warm dish

with cold water has experienced the quick and potentially devastating effects

of thermal shock. This can occur when cold water is introduced to a boiler. The

resulting thermal shock can cause a boiler’s tubes – as well as most any of its

components – to burst or leak.

The solution here is to make sure that your

boiler feedwater is at the proper temperature before being added to the boiler.

5. Improper Boiler Water Treatment (Post

Installation)

Picture this: a company has just spent

thousands of dollars installing a brand-new boiler and is ready to start the

boiler up for operation. To help preserve their investment, they must implement

a proper

water treatment program at this critical

junction. Running the boiler with untreated water will lead to premature

corrosion of the tubes and scaling of the system, potentially leading to a

failure of the boiler itself well before its intended life cycle. Proper boiler

water treatment is essential to maintaining the boiler and keeping maintenance

cost to a minimum. Overlooking this important preventive maintenance activity

will significantly increase downtime, as well as the overall cost of the

system.

Picture this: a company has just spent

thousands of dollars installing a brand-new boiler and is ready to start the

boiler up for operation. To help preserve their investment, they must implement

a proper

water treatment program at this critical

junction. Running the boiler with untreated water will lead to premature

corrosion of the tubes and scaling of the system, potentially leading to a

failure of the boiler itself well before its intended life cycle. Proper boiler

water treatment is essential to maintaining the boiler and keeping maintenance

cost to a minimum. Overlooking this important preventive maintenance activity

will significantly increase downtime, as well as the overall cost of the

system.

HOW TO DO TUBE CORRECTION ?

SHASHIKANT CHAUDHARI

kumarshashikant41@gmail.com

Comments