|

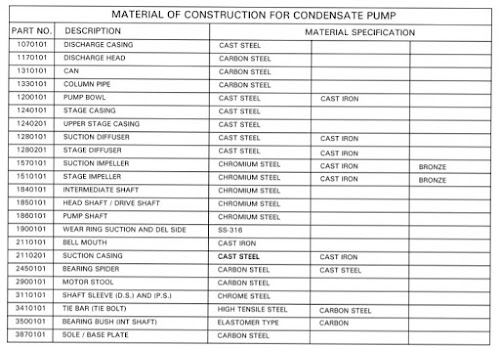

Why is condensate extraction pump used? Condensate Extraction Pumps (CEP) extract the condensate water from the condenser and pump it through the condensate polishing system and the LP heaters to the de-aerator feed water tank. In medium to large size coal- and oil-fired power plants, the CEP are vertical canned type to allow creating artificially enough Net Positive Suction Head Available. In small coal and oil captive Power Plants, the CEP could also be horizontal end-suction type. Different parts of Condensate Extraction Pump Capacity of CEP- Materials using in Manufacturing of CEP - Photos from CEP overhauling works at Site After Safely removed we start punching and marking of de - assembly points    we De- assembly one by one parts and counting marking parts name. we checking parts damage and analyses cause of damage. after find out problems we checking all parts carefully by applying various method like DP test , X- ray and Blue matching. we doing these all process to ensure not any damaged parts in pending that's may make problems in future. we can only CEP overhauling works during shutdown as well as this important part of thermal power plant without CEP we cant run Unit. Here all parts de assembled                    After re- assembly all parts we install again as same position of CEP pump thank you to all......... Shashikant Chaudhari Kumarshashikant41@gmail.com link of video on you tube-------https://www.youtube.com/watch?v=u-DccMEBQP8 |

WHAT IS CEP (CONDENSATE EXTRACTION PUMP) -

This pump is in actual efficiency booster in a thermal power plant. As we all know that very high temperature and pressure steam expands in a steam turbine and this expanded(low pressure and low temp) steam can go waste if CEP doesn't perform it's function. CEP pump circulate the -Condensate(conversion of steam into water in condenser) again into deaerator tank which prevent plant from a huge loss of water. This water can be used for making deaerator level.

Condensate Extraction Pump, as the name suggests the CEP is required to extract the condensate from the Condenser. Condenser is the equipment where all the steam gets condensed and the condensate is extracted out of the same by CEPs. so where the Condensate goes after coming out of the condenser, so it goes to the DEAERATOR by moving through a series of LP heaters, where the temperature of the extracted condensate is increased to a certain degree. In deaerator the soluble gases are extracted out of the condensate by heating it again to a certain a certain degree. and the water stored in deaerator is again fed to the Boiler Feed Pump Suction.

Comments