- By pulverizing to a fine powder and being piped into different burners placed in the furnace of the boiler. Large capacity power plant boilers use this method.

- By circulating fluidized bed where large coal particles spread on to the bottom of the furnace and the air pressure from the bottom keeps it floating to give good combustion.

- Smaller units use grate firing where the coal is spread on a moving or stationary grate, and the combustion air is admitted from below.

Burner Arrangement

THIS IS CHINA BASE BURNER

Coal transportation from the pulverizers to the burners located on the walls of the furnace is through coal pipes. The burners themselves are extensions of theses pipes that pass through the walls of the furnace.

Different manufactures provide different arrangements of the burners on the furnace walls.

1.Tangential firing. In this type, the coal feeds into the furnace at the corners of the furnace. This produces a cyclonic effect in the furnace ensuring proper mixing of air and fuel that is essential for proper combustion. The combustion air also enters into the furnace tangentially above and below these burners. Each pulverizer supplies coal to one level so that the firing is always balanced. In most of the tangential firing systems, the burners can tilt 30 degrees up or down which aids in controlling temperature and combustion conditions. These are called “tangential tilting burners.

2.Wall firing. In this type the burners are placed on the on the front wall or the side walls of the furnace. Each set of burners connects to one pulverizer to maintain balance. The air required for each burner enters the furnace adjacent to the burners.

3.Down-shot firing. In this type the burners are placed in such a way that the flames are pointed downwards. This type is used with anthracitic coals that take more time to burn

Combustion Air in two parts----------

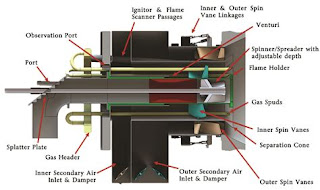

1.Around 25 to 30 % of the air is for drying the coal and transporting the coal. Called primary air this enters the furnace along with the coal through the burners.

2.The remaining air enters the furnace adjacent to the burners from air registers or wind boxes, which are air chambers on the furnace walls, and this is the secondary air. An elaborate control system controls the air pressure and the flow of air from these air registers to the burners.

The burner tips and the air entry points have splitters, twirler's, and vanes to create turbulence at the burner tip. This----

- Ensures proper mixing of the air and coal particles

- Provides sufficient time for the particle to burn

- Makes the ignition temperature available to entering coal particles.

- Prevents the flame from being blown away from the burner while at the same time containing the flame inside the furnace

Comments